On the jacquard loom, starting a new piece. I wove about an inch into the real weaving (after 1.5 inches of border), when forced to stop...

... because I noticed that two warp ends were being lifted much too far. The reason? A colossal case of jammed hooks. Two of 'em, near the front of module 2:

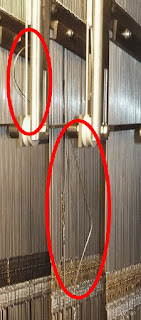

In the photo below, the topmost hook is a new, undamaged one. It's a length of straight steel wire, bent into a 1/3 - 2/3 configuration, then shaped into very small crooks at both ends. The tall end of the hook is sometimes (according to the design) caught by the upper knife; the short end rides on the lower knife (unless the tall end is lifted by the upper knife). The knife positions determine the "floor" and "roof" of the shed.

The lower two hooks are the jammed ones, which DH had to use wire cutters to remove, because they were bent so badly they couldn't be just lifted out. Fortunately, this happens only rarely. Also fortunately, we keep a good supply of spare hooks on hand.

Tuesday, June 23, 2015

Subscribe to:

Post Comments (Atom)

3 comments:

The technology is wonderful...when it works! Kudos to Mike getting it to work!

Cheers

Laura

Are you able to continue after the repair, or do you have to start the piece all over?

Hi, Alice!

After the repairs were done, I resumed weaving, exactly where I left off. There will be some needle-mending to do because there are a couple of very long warp floats on the top. Depending on how those affect the wefts, sometimes scissors are a better repair tool than needle and thread...

Sandra

Post a Comment